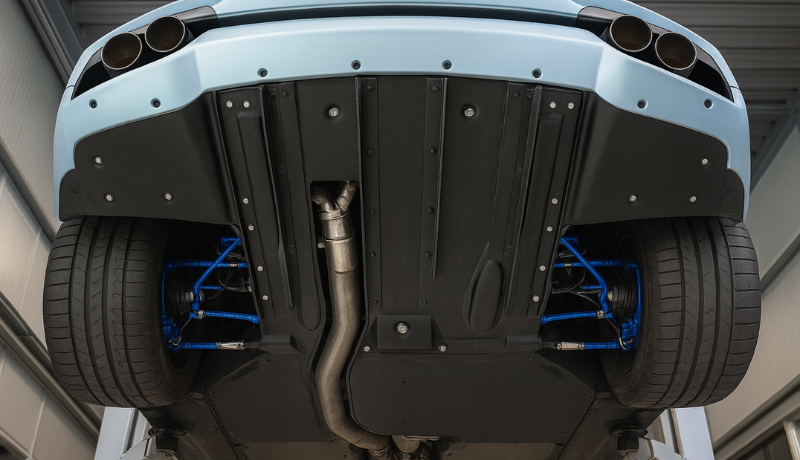

When protecting cars, most think of shiny paint or polished headlights. But the real danger often hides below, which is the car’s underbody. Constantly exposed to water, dirt, and debris, it risks rust and corrosion. This guide explains what underbody coating is, why it matters, and how it keeps your vehicle strong for years.

What is Underbody Coating?

Let’s start with a simple definition of underbody coating:

Definition

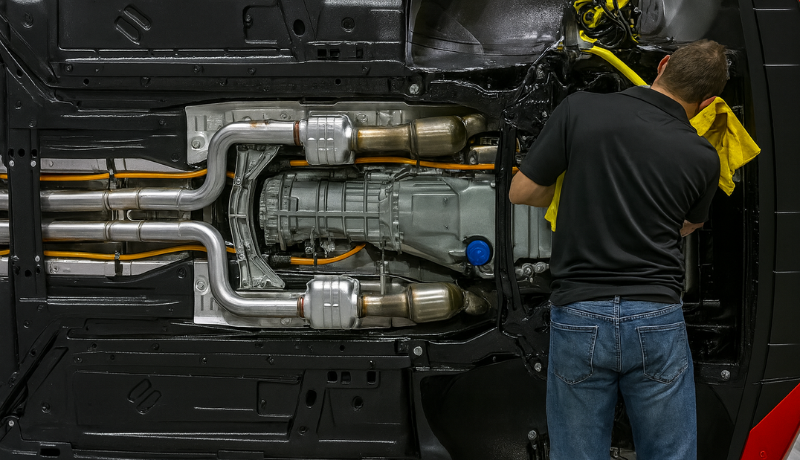

Underbody coating normally refers to the internal protective layer that is applied to the undercarriage of an automobile. It is to be constructed by the floors of the lined chassis, wheel arches, and other external parts.

Purpose

Mainly, it is meant to avoid rust, corrosion, and other damage to the surface. It guarantees a rust-free life for many more years as moisture, salt, and dirt don’t come in contact with bare metals inside.

By adding an extra layer of defense, such as paint protection film, it guarantees a rust-free life for many more years, as moisture, salt, and dirt are kept away from the bare metals inside.

Types of Underbody Coating

Keeping in view the difference in vehicles and driving habits, different coats are chosen. Below is the classification.

Rubberized Underbody Coating

This is the most preferred option for such cars that are not facing heavy-duty usage. It is flexible, so it doesn’t break so commonly; besides, it looks good. An extra benefit is sound absorption; quieter instrumentation becomes a more pleasant journey.

Wax-Based Underbody Coating

For something cheap and simple, wax coatings are the quickest method to use. These are best for a short-term protective layer, but require reapplication more often than other types.

Asphalt Underbody Coating

The best underbody coating, asphalt underbody coating, is a heavy-duty option best used for trucks, RVs, and SUVs only. The density gives it good coverage while driving off-road and, at the same time, makes for very good sound insulation. It is, however, heavy and slightly costlier as compared to the wax and rubberized types.

Polyurethane Underbody Coatings

Polyurethane is widely used in underbody coatings because of its exceptional toughness, flexibility, and strong resistance to abrasion. When applied, it creates a durable layer that seals small cracks and prevents moisture, salt, and road debris from coming into direct contact with the metal.

This barrier not only blocks corrosion but also helps absorb minor impacts from gravel and stones, extending the lifespan of the vehicle’s undercarriage.

Many professionals prefer polyurethane-based solutions for long-lasting protection since they maintain their strength and adhesion over time, even in harsh weather conditions.

Benefits of Underbody Coating

Having an underbody coating is like giving your vehicle a safety net to prevent rust.

Protection from Rust and Corroding Metals

Moisture and salt are threatening metals mostly. The coating creates a barrier between these two from gaining access to the undercarriage. while additional solutions like a car vinyl wrap can provide an extra shield to preserve both appearance and durability.”

Noise Reduction

Underbody coating absorbs vibrations and minimizes the sound created by stones and gravel hitting your car. Long drives are quieter and more enjoyable.

Improved Resale Value

A smooth underside speaks volumes to prospective buyers. With a coating, your car resists oxidation and retains much of its value by maintaining its underbody well.

Weather Protection

In places where it rains heavily or snows, the coating acts like a second armor against water, slush, and salt.

Disadvantages of Underbody Coating

It has its benefits, but underbody coating comes with some disadvantages.

Price

It is expensive to have it done by a professional, especially for larger vehicles. Weighing that against potential costly repairs makes it an investment worth consideration.

Reapplication

As some coatings wear down over time and need reapplication, wax, for example, would require its maintenance at around every year’s end.

Surface Preparation

How clean the undercarriage was before application could determine how efficient the coating was. Not-clean or rusty from the untreated may shorten the life span of the coating.

When to Apply Undercoating for Your Car?

There is really a time factor with respect to making an undercoat work. In instances of proper timing, the undercoat offers maximum protection and longevity.

Before Harsh Weather Conditions

Ideally, coating should be done before the rainy season or the onset of winter. Maximum moisture, road salt, and slush pose a maximum danger to the undercarriage during these two seasons.

It is wiser to protect before corrosion sets in rather than treating it later. Once a surface is corroded, the cost for rust treatments before coating mounts up.

On Brand-New Vehicles

It is easier and cheaper to protect new vehicles from damage. The coating will apply a better metallic look and serve for a longer time, as the floor has not yet rusted and is still factory-fresh. This means that you are starting the life of the car from its first day, almost as if it were an invisible safety net.

For those seeking a bold aesthetic upgrade along with protection, options like a Vantablack wrap can transform the vehicle’s appearance while maintaining its durability, almost like adding an invisible safety net from day one.”

On Older Cars with Proper Preparation

Old cars come with their own advantages too; the only requirement is the fit preparation. The undercarriage needs to be washed well, dried, and after which any rust is treated before the coating is applied. It is like resetting a car entirely.

A clean, smooth base prepares the protection to do its job of preventing any more damage; one that isn’t cleaned will just continue to entrap dirt and corrode beneath it.

During Regular Maintenance Cycles

If you drive in areas with really harsh winters or monsoon climates, it would be a good idea to get a reapplication done every couple of years.

Touching up before extreme weather seasons keeps the protection system working and trustworthy. Regular inspection makes knowing when to make that fresh application simple.

Professional vs. DIY Application

The next big question to settle, once you have decided on under-body coating, is how to apply it, professional or otherwise. Both methods have merits, but which one is right at a part would depend on budget, skill, and expectations.

Professional Application

By going to a certified workshop, one gets really great products, special tools, and trained technicians who know how protective coating and prep get applied to every inch of your undercarriage. That kind of finish, for parts anyway, is uniform and durable for several years. The flip side is the money.

DIY Application

If you are more of a hands-on kind of person and save the price, it seems more attractive under body coating. All you need are these basic resources: face covering, jack or lift, brushes or spray machines, and coating; they can be worked out at home, too.

Actually, the main drawback in the implementation mechanics of the coat would be surface preparation. Once the undercarriage has not been cleaned properly and dries out, the coat will hardly attach.

Furthermore, without materials of a near professional caliber, such an application might even be far inferior to that of a shop application regarding durability.

How to Balance?

Some car owners do not mind this third way: having the work done by a professional, then touch it up or maintain it themselves later. Quite literally, it means getting those years of professional durability with some buck savings at the end.

Two powerful conclusions are:

- Durability, but costly.

- DIY but not costly; they consume much time and require a lot of effort and attention to apply.

FAQ

Q1. Is underbody coating worth it for old cars?

Yes. If it is applied on the properly prepared surface, it can slow down further damage and increase the value of the car on value. Just consider it as buying more time for your vehicle.

Q2. How long does underbody coating last?

Depends on what type it is and what conditions. Rubberized and polyurethane coatings have been known to last years, while waxy ones need touch-ups every year in very harsh climates. A frequent inspection can help determine the reapply period.

Q3. Can underbody coating improve driving comfort?

Yes, it dampens road noise and vibrations, providing you a smoother and quieter ride.

Q4. Are they safe for electric vehicles?

Definitely. Underbody coatings are safe for EVs. They can form a protective barrier without interfering with batteries, wiring, or electronic components.

Conclusion

Cars are built for the rough and tumble road, but one part that is rarely given attention is the undercarriage. This part comes under continuous attack from dirt, water, and road salt as it corrodes silently from within if not protected. Underbody coating is a protective layer to make a stronger car for a long time.

Protect & Upgrade Your Car with Carlike Film

While underbody coatings shield the underside, your car deserves complete protection and unique style. Carlike Film delivers premium vinyl wraps, paint protection films, and window tints that safeguard your car’s surfaces and elevate its appearance.

Trusted by global customers, we help your vehicle look stunning and last longer.

Contact us today for custom solutions!