Cast and calendered vinyl may look similar, but their performance, durability, and cost can differ drastically. Whether you’re wrapping vehicles, creating signage, or choosing films for long-term outdoor use, understanding these differences is essential. Learn how each vinyl is made, why it matters, and how to choose the perfect option for your next project!

What Is Calendered Vinyl?

The calendered vinyl is produced by rolling polyvinyl chloride (PVC), wherein it becomes heated and is rolled through sequential heavy rollers known as calenders. These rollers squeeze and strain material into thin sheets to come up with a film that can be printed and applied.

This manufacturing process produces vinyl that is often thicker than its cast counterpart, usually measuring 3 to 4 mils in thickness. The forming process introduces internal stress on the material, which makes it hard and more rigid.

During manufacturing, the stretching effect provides calendered vinyl with what industry experts refer to as the memory over time, which does not account for existing solvents.

Consequently, causes this material to revert to its initially stretched condition, resulting in shrinkage.

Which is the best use of calendered vinyl?

It has a rigid structure, which ensures that it performs effectively on flat or slightly rounded surfaces where conformability is not a major issue. The banners, window graphics, vinyl wall wraps and decals, wall graphics and flat signage are common applications.

You may also hear it being called in-between vinyl or economy film within the industry, often used for window decals .

According to Grand View Research, the U.S. automobile wrap films market was valued at USD 1.49 billion in 2024 and is predicted to rise at an astounding 18.8% CAGR through 2030.

This highlights the growing need and necessity of using high-quality vinyl materials that can withstand extended exposure to various elements, which is a key factor in their performance .

What Is Cast Vinyl?

Cast vinyl is the highest quality of vinyl film production. Cast vinyl is produced by pouring liquid vinyl resin on a sheet of cast and curing it in ovens, as compared to the mechanical rolling process used in calendered vinyl.

This procedure gives the material time to dry naturally without any mechanical stretching or strain, making a film with better polymer stability. The end product is a very thin film, two mils in depth, which is lightweight, yet highly pliable.

Complex curves, rivets, and recessed places can be wrapped in a cast vinyl wrap without wrinkling or failure, as experienced by calendered vinyl. Vinyl filmshrinkage rate is close to zero as zero stress is applied during the manufacturing process, thus making it the best option when long-term usage is required.

Car wraps are normally good for 5-7 years under good treatment; some costly wraps last more than 10 years, whilst some cheap ones can wear out in 3-4 years.

Complete wraps are always done using cast wrap due to the nature of the material; this has made it the preferred choice among professionals who regard it as the perfect material . i has high conformity, thus making the installation less demanding compared to other types of wraps.

How Cast and Calendered Vinyl Differ

The performance of these two types of vinyl differs in manufacture, producing unique performance characteristics that play a vital role in everyday scenarios. The table below highlights their key differences.

| Feature | Cast Vinyl | Calendered Vinyl |

|---|---|---|

| Manufacturing Process | Made from liquid vinyl cast onto a film and cured | Rolled and pressed through heated rollers |

| Thickness | Thinner (2 mil or less) | Thicker (3–4 mil or more) |

| Flexibility | Highly flexible and comfortable | Less flexible, suited for flat or slightly curved surfaces |

| Durability | Lasts 7–10 years outdoors | Lasts 3–6 years outdoors |

| Finish Quality | Smooth, premium finish | Slightly textured surface |

| Shrinkage | Minimal shrinkage | More prone to shrinkage over time |

| Best Use | Vehicle wraps, complex curves, long-term signage | Short-term signs, flat surfaces, and indoor graphics |

| Cost | More expensive | More affordable |

Factors That Differentiate Cast and Calendered Vinyl

Being aware of the delicate variations between these types of vinyl will enable you to make a wise choice within the scope of your project needs and budget.

Vinyl Shrinking

Dimensional stability is one of the greatest differences between calendered and cast vinyl. Calendared vinyl may shrink by as much as 1/32″ in 24 inches in only 1 year in the environment, and this is increased with time, causing the edges to be lifted or even the collapse of the entire vinyl.

Premium cast vinyl films contract much less, approximately 1/64 over 24 /yr. This drastic discrepancy between shrinkage rates can break or make an installation long-term.

Cast vinyl does not store memory like calendared vinyls, thus shrinkage is negligible – typically reduced by 50 per cent compared to polymeric films.

This superior quality, dimensional stability and adhesive qualities are priceless in outdoor applications, where the polymer experiences years of heating and cooling.

Durability and Weather Resistance.

In terms of resisting the forces encountered in vehicle graphics , cast vinyl is the obvious winner. With proper care, cast and calendered vinyl can last 7 to 10 years or more, respectively.

The high concentration of its molecules gives it outstanding UV resistance, oceanic salt spray, and dampness, as well as temperature extremes.

Premium cast vinyl films have defensive overlayers and UV inhibitors that keep the film 5-12 years away from outdoor breaks.

But calendered vinyl will not have such a barricade and will also deteriorate after less than 1-2 years in extreme settings, which is why it’s often used in common calendered applications .

Conformity Around Curves

This is the place where cast vinyl really pays off. The cast films are generally of high gloss and the most comfortable where there is a complex profiling, such as rivets and corrugations.

Cast vinyl films can easily work with intricate curves and three-dimensional shapes, making them suitable for other applications while conforming without wrinkling, bridging, or forming air pockets.

The thicker and firmer structure of calendered vinyl makes it battle tight curves. Although experienced installers can occasionally coax calendered vinyl around roll-on curves, deep cuts and curved cuts are again out of reach.

Resistance to Abrasion

Cast vinyl has a thicker surface that is smooth and is not prone to scratches and scuffing. Calendered films are heavier in weight and contain a little more of a surface structure, due to which they may become dull or bear scuff marks more easily.

In wrapped trucks and other vehicles where there is frequent washing and impact of debris, this difference will be increased throughout the life of the installation.

Cast Vs Calendered Vinyl Cost Comparison

Budget considerations inevitably dominate vinyl selection, but brand recognition should also play a significant role in your choice.

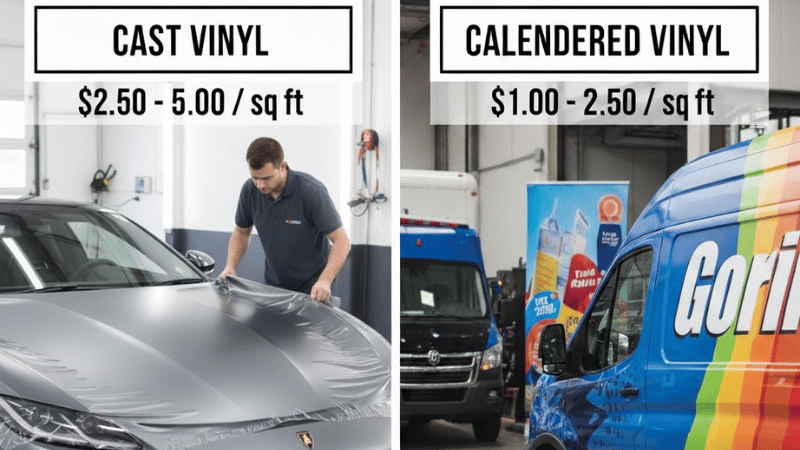

The solid cast vinyl film is generally priced at $2.5 to $5.00 per square foot for the material alone, partly due to its large-diameter core.

In comparison, calendered vinyl costs $1.00 to $2.50 per square foot, making it a more cost-effective option at roughly half the price.

Nevertheless, this initial fee disparity does not reflect the full financial picture.

A commercial vinyl wrap that only lasts about three years is usually made from calendered film.

Because it needs to be replaced so often, the long-term cost can end up higher than a cast wrap, which can last up to ten years.

In most cases, when you do your calculations on the specific amount of cost per year, cast vinyl can be the cheaper option when it comes to long-term use.

| Cost Factor | Cast Vinyl | Calendered Vinyl |

|---|---|---|

| Material Cost per sq ft | $8–$16 | $1.5–$8 |

| Material for 250 sq ft | $2,000–$4,000 | $375–$2,500 |

| Full Vehicle Wrap (total) | $2,000–$6,000 | $1000-3500 |

| Durability | 7–10 years | 3–5 years |

| Cost per Year | $200–$1000/year | $200–$1167/year |

Which Vinyl Should You Choose?

The correct choice of the vinyl is a question of identifying the material properties that can meet your requirements. The correct vinyl is based on the surface shape, surroundings, and the durability of the project.

Choose Cast Vinyl If:

- You are enveloping a car or any surface that has complicated curves.

- You require a durable finish (7 or more years)

- The installation will be subjected to tough exterior conditions.

- Your budget is able to afford an increased initial expense with greater long-term value.

Choose Calendered Vinyl If:

- You are making temporary promotion artwork or seasonal adverts.

- The surface on which the application is done is flat or has only slight curves.

- You have a limited budget.

- The project life cycle is less than 3 years.

| Application | Recommended Type | Why |

|---|---|---|

| Vehicle wraps | Cast vinyl films | Handles curves, durable finish |

| Store signage | Calendered vinyl films | Flat surfaces, cost-effective |

| Fleet graphics | Cast vinyl films | UV and weather resistant |

| Temporary event graphics | Calendered vinyl films | Easy to apply/remove |

| Outdoor advertising | Cast vinyl films | Long-term exposure protection |

Common Mistakes When Choosing Vinyl Film

Here are a few mistakes that most people make while selecting vinyl film:

1- Selecting by price: The most affordable in the short run may not be as cheap when you include the cost of early replacement, and labor to install the hardware again.

2- Vinyl on curvy things: Calendered films are applied to surfaces that are flat, or that have simple curves, and, as the weather changes, and the film is subjected to heating and cooling, they contract and crack as they attempt to reshape themselves to the preset shape.

3- Ignoring environmental influences: In places like San Diego, summer UV levels can reach 9–11, which causes vinyl wraps to break down faster through UV damage.

However, the consistently warm climate, with no freeze-thaw cycles, helps the wrap last longer.

4- Neglecting brand quality diversification: When selecting well-known brands, you are guaranteed that you are buying the performance properties that you are paying for.

Major producers such as Carlike provide branded cast and calendered product lines in different quality levels.

FAQs

Q1. Why know the distinction between cast and calendered vinyl?

Making the right choice will guarantee long-term outcomes and avoid costly renegotiation or overhaul.

Q2. Is cast vinyl always better?

No. In the case of 2D, short to mid-term (2+ years) applications, calendared is preferable, and cast film is preferable to long-term (4+ years), 3D applications.

Q3. Why are there all types of professionals?

Each has other demands–cast to endurance and adaptability, calibrated to economies of price and quantity.

Q4. What was the effect of vinyl choice on cost?

The right selection, considering a few factors, lowers maintenance, inhibits peeling, and maximizes ROI over time.

Conclusion

Choosing cast or calendered vinyl depends on how well each material fits your project needs. Cast vinyl offers superior durability, conformability, and long-term performance, making it the professional standard for vehicle wraps and outdoor applications.

Calendered vinyl is more affordable and suitable for flat surfaces or short-term use. Understanding these differences helps you make cost-effective decisions without compromising performance.

Carlike — Your Fast, Flexible, and Quality-Driven Vinyl Solution!

Carlike makes a distinction by combining quality, timeliness, and service, including flexible vinyl, to help you expand your business. Enjoy low MOQ, high-quality vinyl, and customized OEM/ODM solutions tailored to your brand.

With lightning-fast production and 24-hour professional assistance, your success begins right away.

Get in touch with us right now to begin your purchase and receive your customized price!