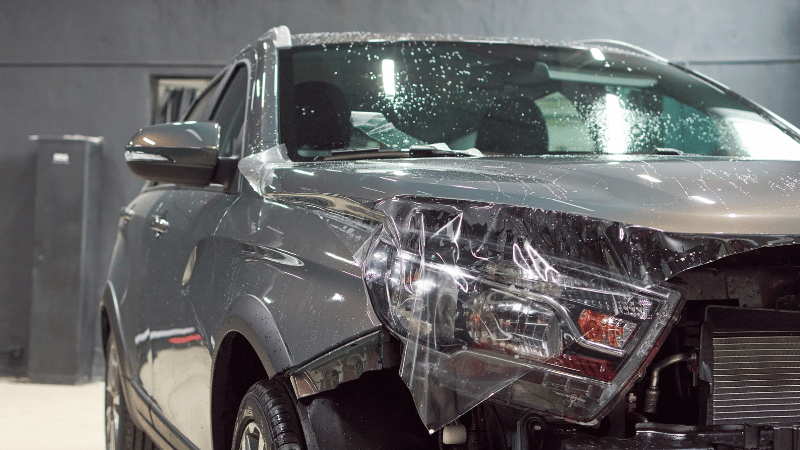

Paint protection films become a superhero cape for vehicles and deflect all the hostile road elements away from the car’s paint. Knowing the differences between high-quality vs low-quality films can help you choose the best option. This article breaks down all the details of high-end PPFs so that you can choose wisely.

What Does PPF Mean? Understanding the Basics

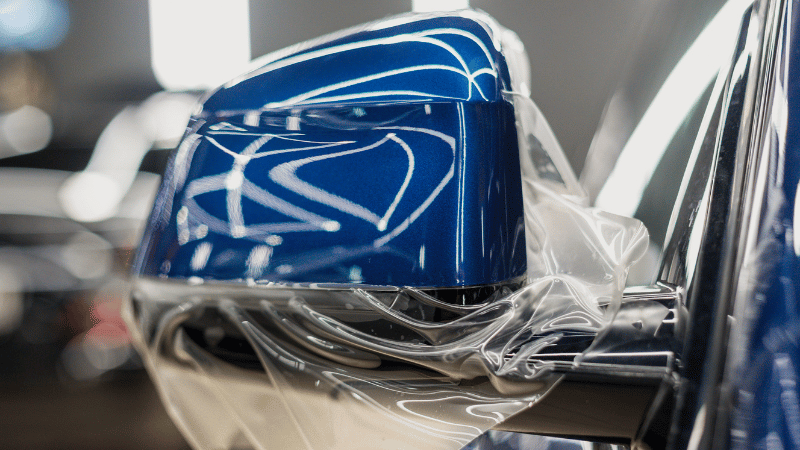

The term PPF is an abbreviation for “paint protection film,” which is a transparent, flexible sheet made up of Thermoplastic polyurethane (TPU). As the name says all, it is a film that quite literally protects the vehicle’s paint from everyday wear and tear that occurs due to the brutal assaults of road elements.

It locks in the vehicle’s aesthetic appeal as well as keeps the car’s paint in its factory-grade finish to preserve its resale value.

Working Mechanism

Being an elastomeric film, a PPF exhibits stretchable properties and hence is applied on the vehicle’s surface as a laminating layer that envelops the exterior. Think of it as a stunt double for the underlying paint that takes the rock chips, the scratches, the gravel hits, and much more environmental hazards, so the “star” underneath remains flawless.

Evolution of PPF: Then Vs. Now

The PPFs that are famously being used as protective films were not manufactured in the form we recognize now. The benefits that clear bra offers now are achieved through years of evolution and reformulation of the film.

This section highlights key differences between earlier-generation PPFs and the advanced films available today.

Old-Generation PPF

The journey of paint protection films dates back to the Vietnam War, when they served as protective films for helicopter blades. Soon, these films made their way into the automotive industry; however, those iterations had simpler formulations with PVC or filler-infused TPU.

Due to this, those PPFs had notable limitations, like yellowing, cracking, short lifespan, and much more.

Advanced PPF

With the continuous reformulation, the thermoplastic urethane-based PPFs that are now available in the market have achieved significant milestones in terms of protective qualities. The following are the features that only a high-quality PPF exhibits.

UV Rays Resistance: To counter the yellowing and dulling of the PPFs due to harmful UV rays, PPF manufacturers infused ceramic coating with the films. This improvement added the property of UV resistance.

Self-Healing Properties: The most revolutionary advancement in the PPF quality was the introduction of self-healing capabilities through nanotechnology. At the microscopic level, thermo-active polymers were included in these PPFs, which rearrange themselves upon heat exposure.

Thus, such films were able to smooth minor scratches and abrasions just with heat exposure.

Hydrophobic Layer: Another breakthrough in PPF evolution is the addition of a hydrophobic topcoat to add resistance against dirt, grime, and water spotting.

Improved Clarity: High-quality paint protection films are also made to be virtually invisible, so that they don’t interfere with the aesthetics of the car’s paint.

Materials Used in PPF: TPU vs TPH vs PVC

A paint protection film is essentially a sheet made up of plastomeric polymers with protective capabilities. Now, there are different types of polymers, and the choice of base polymer directly defines how a PPF behaves.

Therefore, in this section, we break down the various polymers used as core materials and compare the differences in properties they impart.

TPU-based PPF

This PPF is manufactured with Thermoplastic Polyurethane (TPU) polymer, a polymer known for its superior qualities. TPU-based PPF falls under the category of premium protection film, which provides superior protection compared to its counterparts.

They are durable films and have optical clarity so high that they look almost invisible on the car. The installation of TPU PPF on fleet vehicles requires certified installers to achieve a smooth finish.

TPH-based PPF

TPH stands for Thermoplastic Hybrid. This type of PPF uses a blend of different polymers to create a formulation that remains budget-friendly while still delivering essential protective features. A TPH-based PPF has a shorter life span and belongs to the category of mid-tier PPF products.

PVC-based PPF

The PPFs that are manufactured with Polyvinyl Chloride (PVC) polymer only provide basic protection without added functionalities like self-healing and resistance to UV exposure. These PPFs resemble vinyl wraps but are colorless and have significant limitations compared to other PPF options.

Head-to-Head Comparison

We have put all three types of paint protection films in a head-to-head comparison so that you can compare the features of each and decide on a suitable option for yourself.

| Characteristics | TPU Film | TPH Film | PVC Film |

|---|---|---|---|

| Durability | Highly durable & have self-healing properties | Moderately durable and can withstand scratches | Low impact resistance |

| Clarity | High optical clarity and feel almost invisible | Decent visual clarity | Vulnerable to discoloration and dullness |

| Stretchibility | Highly conformable and can adapt well to contours | Better stretchability than PVC-based PPFs | Difficult to conform to curved surfaces |

| Cost Considerations | Expensive and premium option | Cost-effective | Cheapest option in the market |

| Life Span | 8 - 10 years with a maintenance routine | 2 - 5 years | 1 - 2 years |

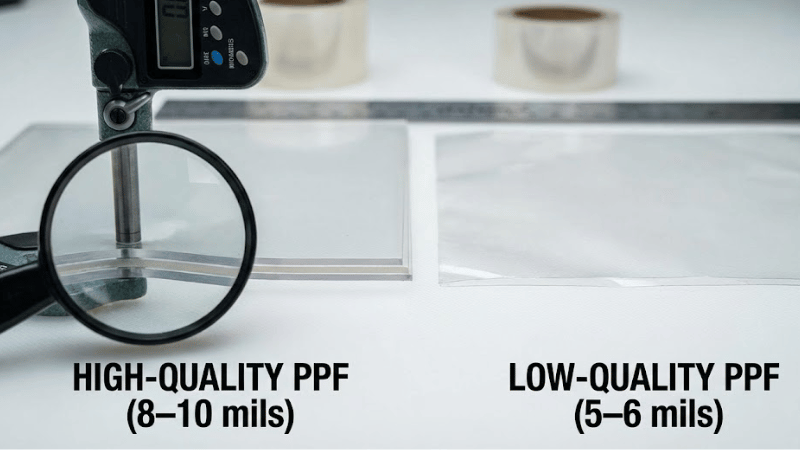

PPF Thickness: Does Thicker Mean Better?

It is commonly perceived that thicker ppf always means better; however, this concept does not exactly apply when it comes to the paint protection films. Although the paint protection film thickness matters, the main factor to consider is the base material.

A low-quality PPF with decent thickness can still feel rubber-like and crack faster. Therefore, the thickness and the material quality go hand-in-hand and complement each other.

Ideal Thickness Range

Whether you choose a high-quality PPF or a low-quality PPF, there is a certain thickness range that works for either type. The following are the ranges of thickness you should look for to achieve optimal performance of a PPF.

- High-Quality PPF: The right PPF thickness for a high-quality film is somewhere between 8–10 mils. This thickness strikes the right balance as it is thick enough to absorb the impact of debris flying off from the road, yet flexible enough to conform with ease.

- Low-Quality PPF: The appropriate thickness of a low-quality PPF is 5–6 mils. These films are already difficult to conform neatly to the surfaces, and higher thickness can make them more brittle. Therefore, the optimal thickness for mid-range PPFs must be less than 6 mils.

Durability & Resistance Differences

The selection among high-quality PPF and its cost-effective alternatives is entirely a matter of personal preference. A car owner may have the budget to afford a premium PPF yet still opt for a PVC-based colored PPF if the goal is a short-term solution.

However, you still must know the differences between the features of both to make the right choice.

Discoloration Resistance

Advanced PPFs are manufacture to have an enhanced resistance to the direct sunlight so that yellowing and discoloration can be prevented. However, a low-quality film tends to get yellow within a few months, muting the appearance of your vehicle.

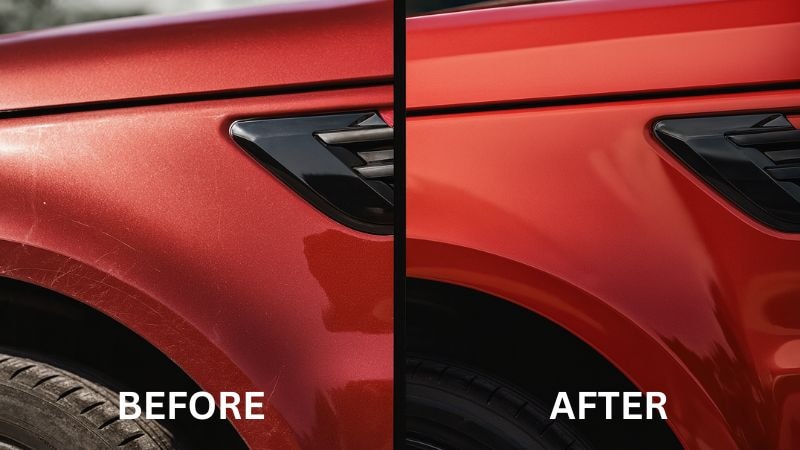

Scratch Protection

Quality paint protection films are also equipped with self-healing properties, which means minor wear and tear will heal all on its own. In contrast, low-quality PPFs lack scratch-recovery capability, which causes damage to remain visible and also shortens the film’s lifespan.

Cracking

Even if you don’t require long-term durability and better protection, you should still go for a high-end PPF option because it resists cracking even after months of use.

However, low-quality films are prone to cracking around the corners, which means you do not even get the short-term protection you initially installed the film for.

Chemical Resistance

In terms of chemical resistance, quality paint protection films again have a one plus over low-quality PPFs. Cheap PPFs have a thin topcoat and are prone to showing wear and tear quicker than the superior PPFs.

Optical Clarity

A high-end PPF becomes the second skin of the vehicle’s surface and looks completely invisible, while the cheaper options are highly susceptible to the orange peel effect.Moreover, cheaper films also tend to cause the chipping of the vehicle’s paint when these films are removed.

Cost vs Value: How a Cheap PPF Ends Up Costing More

Choosing a low-quality PPF may save you a few pennies now; however, it will cost you more in the long run by causing other damage.

As a vehicle owner, you must consider PPF as an investment in the health of your four-wheeler. Therefore, choose the right paint protection film even if it means spending a little more.

Cost Breakdown

The installation of a high-quality PPF can cost between $3,000 to over $8,000 USD. This cost greatly depends on your vehicle’s size and on whether you opt for professional PPF installation or local.

While this upfront cost seems higher, it works as your one-time investment and lasts around 8–10 years if proper care is maintained.

On the other hand, a low-quality PPF has a much cheaper upfront cost. However, not only that it fail within 1 – 2 years, but it also comes with hidden costs.

In the end, when you factor in those hidden expenses, the total cost ends up being equal to what you would have spent on a high-quality PPF in the first place.

- Peeling and Paint Damage: As the low-end films tend to crack and peel off, they expose the painted surface to the hostile road conditions. As a result, the purpose of PPF installation gets lost, and the car’s paint gets damaged.

- Frequent Touch Ups: You might have to make frequent workshop runs to get the touch-ups done.

- Resale Value: Another cost-draining factor is the diminishing of the resale value because the original paint is not truly protected.

Conclusion

A high-quality PPF stands as the ultimate choice for paint protection as it comes with value-added features of self-healing, UV resistance, and long lifespan. You might get basic protection from a low-quality film, but it also has its own demerits. So, if you are after all investing in a PPF, you must do it wisely because paying once more saves repeated regret.

Improve Your Profits With High-Quality PPFs from Carlike®

Being the prime manufacturer of high-quality automotive films, CarLike Films has become a trusted name in the industry. We provide businesses with a consistent supply of high-quality PPFs. You can place your bulk order anytime, and we will produce and ship it in no time so that your business keeps going.

So, choose CarLike as your films supplier and unlock exclusive discounts on bulk orders. Contact us today, and our professionals will create a customized package as per your business needs.

FAQs

Q1: How long does high-quality PPF last?

The lifespan of a high-quality PPF falls between 8 to 10 years. However, this life expectancy also significantly depends on the driving habits and after-care routine.

Q2: Does PPF damage paint when removed?

A PPF may or may not damage the paint upon removal, depending upon the quality of the PPF itself. High-end PPFs tend to smoothly peel off from the surface, while a low-quality PPF can cause chipping of the paint while coming off.

Q3: Can you provide samples or colour cards?

Yes, we can provide you with samples and colour cards before your order. Our colour card features hundreds of colours, and you can choose from it according to your market needs.

Q4: What is your warranty policy?

At CarLike, we offer all of our products with a 2-year warranty. Our products are engineered to deliver enhanced performance in the first place, so issues rarely occur. However, if any quality problem does arise, we stand by our commitment and replace the product without hesitation.