Pre cut tint kits are revolutionizing the way shops used to offer window tinting solutions. With precut tints, fleet managers can save time associated with measuring and cutting the tint rolls, reducing waste. This guide explains what precut tint kits are, their significance to businesses, and their benefits. Read on!

What Are Precut Tint Kits?

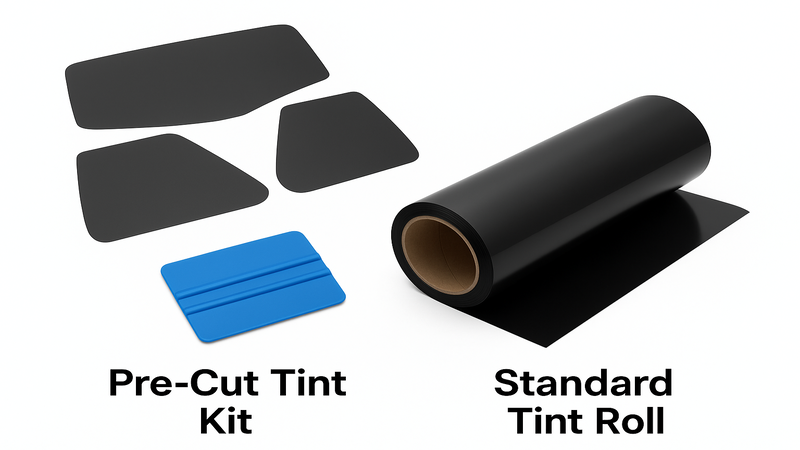

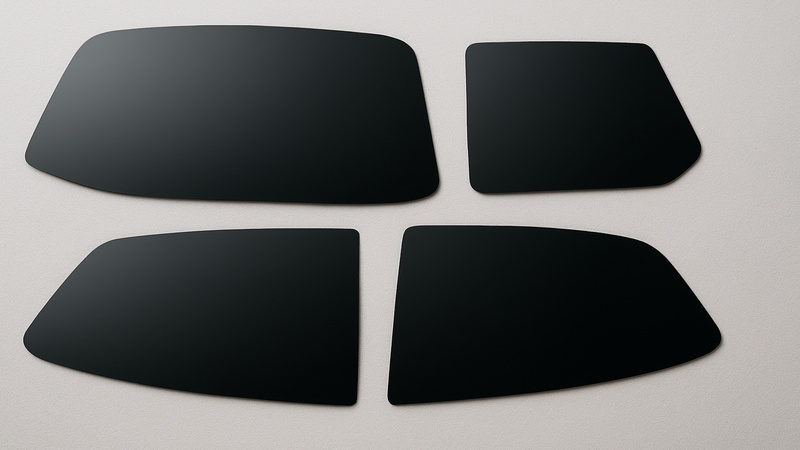

Precut window tint kits are ready-to-install window tints that are designed to match the exact shape and size of vehicle windows. Using precut tints saves your effort and time associated with measuring the vehicle windows and trimming film from a roll.

The pre-measured and pre-cut pieces make installation quick and reliable. Many precut tint kits come with application tools and pre-labelled pieces to assist technicians.

Precut tint kits are made using the digital templates and pattern libraries. The precut kits match OEM window shapes and standards, allowing buyers to purchase them with confidence, knowing the film will fit specific vehicle models.

Buyers such as fleet owners, dealerships, and auto shops looking for a solution to improve efficiency should definitely consider precut kits. Thanks to the easy installation process, these kits even make it possible for beginners to install them accurately.

Why Precut Kits Matter to Businesses?

In the absence of pre-cut tint kits, fleet owners and busy shops must measure the vehicle’s window dimensions and then trim the tint from the roll. This process is both time-consuming and challenging.

To save time, precut window tint kits come to the rescue, allowing technicians to offer window tinting solutions for multiple vehicles in a single day. For businesses, pre-cut tint kits are helpful as faster installation reduces labour costs.

Measuring vehicles, cutting from rolls, and installing the tint can take up to two hours, whereas precut kits can complete the job in under 15 minutes. This results in increased productivity and helps employees with time management.

Another reason precut kits matter is that they reduce material waste. Instead of cutting from rolls, precut kits provide exactly the tint needed for each window. This reduces waste and makes it easier for businesses to manage their inventory.

Accuracy also drives shops and fleet managers to switch to precut kits. With fewer mistakes, businesses can retain clients and improve satisfaction. The ease of installation even allows fleet managers to handle tinting themselves without relying heavily on third parties, further reducing costs.

Lastly, with reliable quality and predictable margins, precut tint kits are ideal for businesses seeking to expand and scale their profits profitably.

Types of Precut Kits & Technologies

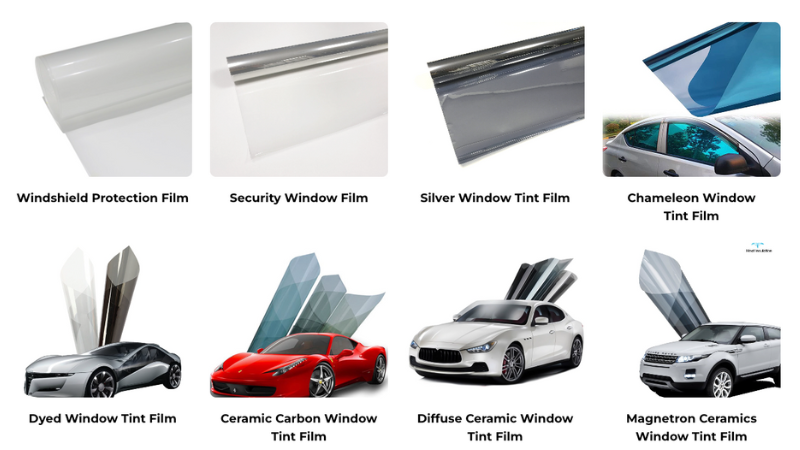

There are different types of window tint, and pre-cut window tint kits, along with their subtypes, are a popular choice. As a fleet manager or business owner, you can choose the one that is suitable for your demands, budget, and performance requirements.

Shared below are the types and technologies of precut kits that can help you find the right option for your needs:

1. Basic Precut Kit:

These window tint pre-cut kits feature standard carbon or dyed film tint. These kits are cost-effective and suitable for those looking for budget-conscious options. If you have to tint vehicle windows in bulk, then this kit is helpful.

2. Premium Precut Kit:

This kit features hybrid or ceramic film. These kits provide excellent heat rejection by blocking harmful UV rays and IR rays from entering the cabin. The premium precut kit is long-lasting and offers the highest level of comfort.

Premium buyers mostly opt for these precut window tint kits. Protecting this tint to improve its longevity is also very easy, which further enhances its popularity.

3. IR/Heat-Rejecting Precut Kits

These pre-cut kits are made of advanced materials, such as metallized film. The advanced material blocks the IR radiation from entering the cabin while maintaining higher visible light transmission. These pre-cut kits are ideal in cases where darker tints are against the local tint laws.

In addition to the above three types, precut tints are also categorized based on cut-by-model kits versus universal kits. Cut-by-model, as the name indicates, guarantees a perfect fit for specific vehicle models.

Universal cut, on the other hand, is flexible and may need minor cutting to fit the vehicle. Universal cuts have a lower upfront cost. Thus, choosing between these models depends on whether a fleet owner values speed and accuracy or the lower initial cost.

Tint Films’ Performance Criteria That Matter to B2B Buyers

When purchasing precut tint kits, buyers require assurance that the film will perform effectively in the long run. Shops, fleet owners, and dealers evaluate the following criteria to invest in film that will deliver them value:

1. Film Material and Technology

The efficiency of the film depends on its material and the technology used. Heat rejection, durability, and appearance are determined by the choice between dyed, carbon, hybrid, or ceramic films.

Premium options offer the best performance. Therefore, buyers need to evaluate the film material and technology and invest in one that suits their specific goals.

2. TSER / IR Rejection and UV Protection

TSER measures how much light and heat the tint can block. A higher TSER is linked with better comfort. Pre cut window film kits that block heat by up to 99% keep the cabin cool and offer drivers maximum comfort.

Similarly, the tints offering supreme UV protection are the best option. TSER, UV protection, sun protection, and IR rejection offered by a tint must be evaluated by businesses before investing in it.

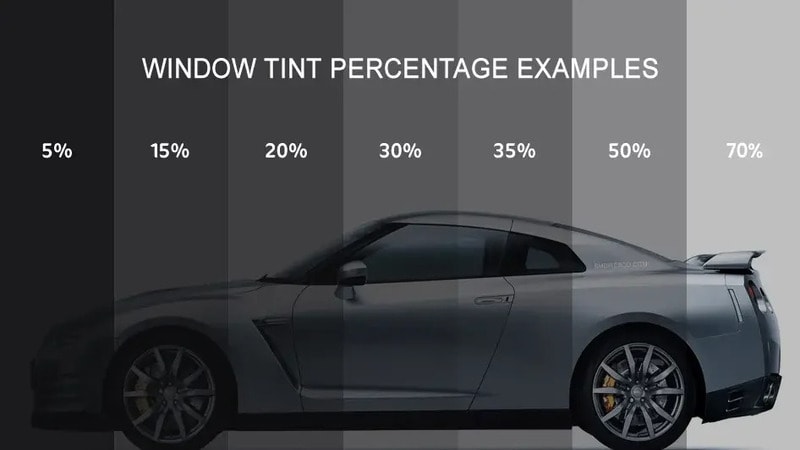

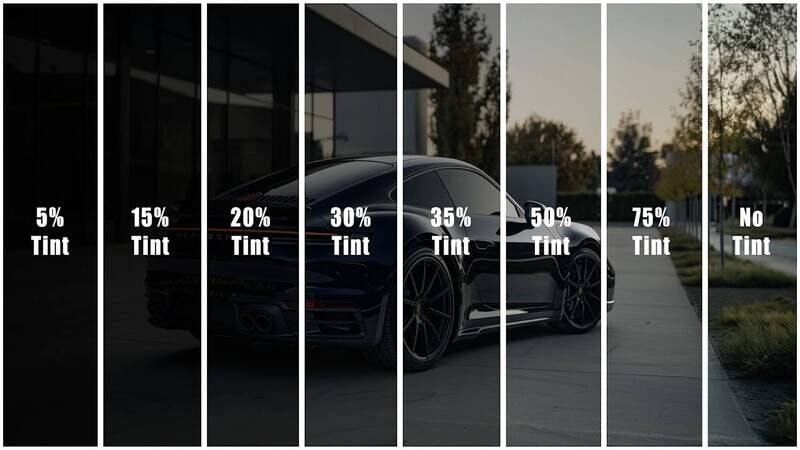

3. VLT Options

Pre cut window tint films come with different visible light transmission (VLT) options. Businesses should choose the legal one that aligns with local tint laws and regulations, while also matching the comfort level required by customers.

4. Adhesive Quality

Kits that peel off or show edge shrinkage are a big no. As a business owner, you need to invest in high-quality, adhesive, precut window tint to ensure a bubble-free installation.

5. Durability

The durability and longevity of pre-cut films cannot be ignored. Films that are scratch-resistant, color stable, and unlikely to fade over time should be preferred over low-quality tints.

6. Warranty and Supplier Reliability

Selecting a reliable supplier ensures consistent window tint pre cut quality, while robust warranty coverage safeguards against product defects and rework. This reduces risks and builds customer trust.

By evaluating all these performance measures, businesses can make informed decisions, improve customer satisfaction, and increase profit margins.

Installation Workflow Using Precut Kits

The ease of installation compels businesses to switch from roll films to pre-cut window tint kits. The steps mentioned below will help you seamlessly install these kits:

Tools Needed for Installation

For installing the pre cut window tint, you need a squeegee (to smooth out the film), a heat gun, a spray bottle with slip solution, a soft/microfiber cloth, and a blade for trimming. Luckily, some of the kits are pre-measured, which means fewer cutting tools are required.

Step-by-Step Install Guide

The step-by-step installation process of the precut kits is mentioned below:

Step 1 – Preparation

Start by wiping off any dust from the windows. Cleaning the vehicle windows ensures that the adhesion will be strong.

Step 2 – Fit Check

Next, match each labelled piece to the window to ensure an accurate fit. Once you are sure that the tint matches the vehicle’s window size, peel off the liner.

Step 3 – Application

Spray the slip solution on the window and on the adhesive side of the film. Align the tint and smooth it out using the squeegee.

Step 4 – Curing

Now, using a microfiber towel, remove any excess moisture and ensure the tint is tightly bonded to the window glass. This step will ensure the tint lasts for a longer period.

Step 5 – Quality Check

After attaching the tint to the glass, inspect it for bubbles, peeling edges, and alignment issues. Once satisfied, you can hand over the vehicle to the owner.

With pre-cut window tint films, managers can easily hire new technicians as the pre-cut kits already eliminate the most crucial step of measuring and cutting. Installing precut tint kits doesn’t take a long time.

Cost Analysis: Upfront vs. Lifetime Value

When deciding whether to choose traditional window tint film, one factor that influences the decision the most is the cost associated with buying it.

The precut kits may cost more initially, but when evaluated over their lifetime of use, they prove to be more cost-effective. The side-by-side comparison of traditional roll films and precut kits is given below. Take a look at this table to see the preferred choice for your business needs:

| Factor | Traditional Roll Film | Precut Tint Kits |

|---|---|---|

| Upfront Material Cost | Lower per square foot | Slightly higher per kit |

| Installation Time | 1.5 – 2 hours per vehicle | 15 – 20 minutes per vehicle |

| Labor Cost | High (more technician hours required) | Low (fast installs, less staffing) |

| Material Waste | High (mis-cuts, trimming, leftover film) | Extremely low (pre-measured, exact fit) |

| Accuracy & Fit | Depends on the skill of the installer | Guaranteed accurate fit |

| Training Needs | Requires skilled technicians | Easy for new staff to learn |

| Customer Satisfaction | Risk of errors, delays | Consistent quality, faster delivery |

| Lifetime Value | Lower profit margins | Higher profitability and efficiency |

How to Prevent Common Quality Issues in Precut Kits?

Miscut pieces, poor adhesion, edge peeling, and inconsistent VLT are the primary concerns for businesses using precut window films. These defects not only reduce profit margins but also contribute to customer dissatisfaction.

To prevent common issues with precut kits, it is essential to choose suppliers carefully. Also, make sure to request sample kits before buying in bulk and inspect the sample kit for adhesion, quality, and pattern accuracy.

Carlike Film specializes in high-quality car window tint films. You can contact us to get free samples to assess their quality and performance.

To prevent common quality issues, ensure that you set up an on-site quality assurance process. Lastly, make a checklist to track the quality, measurements, and adhesion layers of the new batch of precut window film as soon as it’s received.

Also, before installation, conduct a pre-install inspection check to detect any potential problems.

Legal & Compliance Considerations

To avoid hefty fines, penalties, and liability risks, businesses investing in precut tint kits must consider the legal window tint percentage.

To ensure compliance, businesses should:

- Keep proper VLT documentation and labelling for all vehicles.

- Maintain a compliance matrix to ensure the right tint option is used in each region.

- Guide customers to choose a standard and legal VLT precut tint, and document customer sign-off for any non-standard VLT choices.

Boosting Revenue with Precut Kits

Reaping the benefits of window tinting and driving revenue using precut window tints is simple and easy. Shops or dealerships can market the precut kits as quick-install options to get the attention of customers who value speed and quality.

By offering basic, standard, and premium tiered packages, shops and dealerships can allow customers to choose the package that best suits their needs and budget. Shops can also bundle pre cut kit tint installation with ceramic coating or PPF to offer more value and attract more customers.

Lastly, by offering warranty-backed installation, dealers providing precut kit tint installation can differentiate themselves from competitors and satisfy the clients.

FAQs

Q1. How precise are precut tint kits compared to manual cutting?

Precut tint kits are designed based on digital patterns to match the exact size of a specific vehicle, ensuring a precise fit. Manual cutting, on the other hand, requires the technician to cut the tint from a roll and trim it to match the vehicle’s window size, and thus is not very precise.

Q2. Do precut kits reduce installation time for shops?

Yes, by eliminating the measuring and trimming step, precut kits do reduce installation time for shops. It takes around 1.5 to 2 hours for a technician to apply traditional tint to a vehicle. In contrast, it takes a technician only 15 minutes to provide a tinting solution to a car using the pre-cut tint kit.

Q3: Do precut tint kits improve installation quality?

Yes, they reduce cutting errors, air bubbles, and uneven edges, giving a professional finish even for DIY users.

Conclusion

The quick and simple installation, combined with reduced waste and effective utilisation of staff time, makes precut tint kits superior to other options. Fleet managers must switch to the precut kit tint option to save time and effort and to maximise the return on investment.

To drive more revenue using pre cut tint, always ensure to partner with a reputable supplier.

Maximize Your Profit Margins with Carlike‘s Premium Tint Films

Carlike Film, with more than a decade of experience in manufacturing top-quality PPF, car wraps, and window tints, is here to offer you the best window tinting solutions. Whether you need ceramic tint rolls or dyed window tint film, our experienced staff can meet all your requirements.

Contact us to get a bulk quote tailored to your requirements! Upgrade your fleet today.