Choosing the right light bulb goes beyond brightness—it impacts energy savings, comfort, and long-term costs. In this guide, we reveal the 10 best light bulb brands for homes and businesses in 2026, compare key features, explain essential bulb basics, and help you select the perfect lighting solution for any application.

What Is Self-Adhesive Vinyl?

Self-adhesive vinyl, also known as SAV, is essentially a PVC film having a pressure-sensitive adhesive layered on one side to make the film ready-to-stick. These peel-and-stick films spare the hassle of needing additional glue, as well as have a front material of polyvinyl chloride that makes the film flexible and conformable.

Being pliable and printable, these self-adhesive vinyl sheets have found application across versatile industries of different natures.

What Does “Self-Adhesive” Mean?

Self-adhesive refers to a vinyl film that sticks on its own without the need to apply an additional layer of external glue or fastener. At the microscopic level, once the adhesion touches the surface, the Van der Waals forces start acting between the adhesive and the surface, and the pressure application increases the contact area.

The adhesive backing gets activated upon exposure to pressure and strongly sticks to the surface it is being applied to.

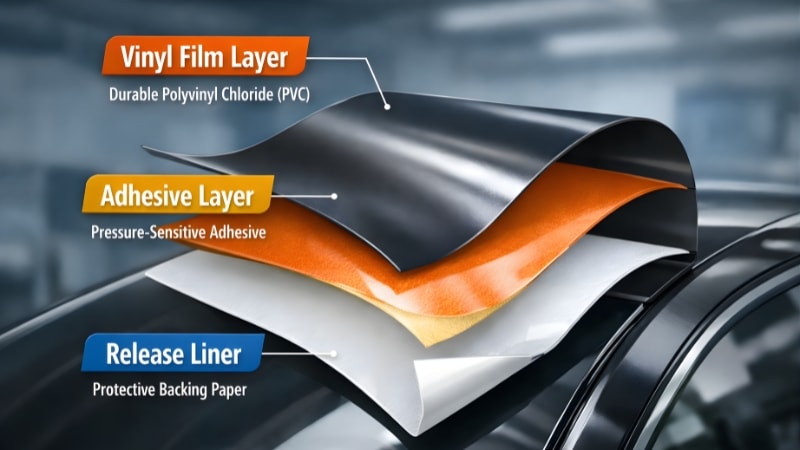

Structure of Adhesive Vinyl

Understanding the structure of an adhesive-backed vinyl film is the key to mastering its application. It’s not rocket science; once you know what each layer does, the entire process starts to make sense.

Structurally, a vinyl film is made up of three different foundational layers that are laminated together on top of each other to make the final product of a cohesive film.

- Vinyl Film Layer: First comes the face layer composed of polyvinyl chloride polymer, which adds the functionality of flexibility and durability to the film. This vinyl film layer is printable and, therefore, facilitates versatile applications.

- Adhesive Layer: Right below the top film lies the layer of pressure-sensitive acrylic adhesive that plays the role of bonding the vinyl to the surface.

- Release Liner: In the last, the adhesive layer is covered with a release liner that protects the adhesive before application and supports the vinyl during handling. This backing paper makes sure the adhesive is not exposed to irrelevant surfaces.

Types of Self-Adhesive Vinyl

Self-adhesive vinyl films are made in different varieties by manufacturing them with a different process. This difference in the manufacturing process imparts different properties to the vinyl films, settingsome options superior to the others in terms of performance.

Knowing the properties of each type of film, you will be able to select one according to your needs.

Calendered Vinyl

Calendered vinyls are a popular choice for short-term applications since they are less durable and flexible than their counterparts. These films are slightly thicker and, therefore, are more suitable for flat surfaces rather than the curved ones.

- Manufacturing Process: Calendered vinyls are manufactured through calendering films in which the vinyl resin paste is extruded through a series of heated rollers to harden and flatten it.

- Cost Advantages: Having limited conformability and shorter lifespans, these calendered rolls fall in a cost-effective category.

- Best Uses: Calendered vinyl rolls are best suited for flat surfaces and short to medium-term graphics. They are also used for signature and decals for for both individuals and businesses.

Cast Vinyl

Cast vinyl rolls are flexible films that subtly conform to curved and contoured surfaces as well as flat surfaces. These are considered high-performance vinyls because of better material quality and the ideal thickness of two mills.

- Manufacturing Process: Cast films are manufactured by pouring the liquid vinyl into casting sheets and carefully curing them in ovens under optimum conditions. This process allows the polymer molecules to settle naturally without mechanical strain, as in calendered films.

- Cost Advantages: In cast vs calendered, the former is considered a high-quality product and therefore, features a higher price tag. However, with superior conformability to complex shapes and a long lifespan, these vinyl films prove to be a long-term investment.

- Best Uses: These films are ideal for vehicle wraps and outdoor applications on vinyl billboards.

Specialty Vinyl

The vinyl films that offer a value-added feature apart from the basic function of wrapping and coverage are categorized under specialty vinyls. These films are made to be UV-resistant and waterproof so that they last longer and protect better.

- Characteristics: These wraps come in unique finishes like carbon fiber, holographic, iridescent, and chameleon.

- Best Uses: These vinyls serve best as decorative elements to be used in commercial places. Additionally, they can also be employed as decorative vinyls at home for interior designing and renovation.

What Is Adhesive Vinyl Used For?

Given the ease of application and versatility of self-adhesive vinyls, they have found widespread application across the industries of different types. In this section, we will discuss how adhesive-backed vinyls are being employed for different uses.

Product Labels and Vinyl Stickers

Instead of paper, vinyl stickers are now being widely used for branding, labelling, and packaging of different products, given their moisture and temperature resistance. Vinyl labels feature sharper lettering and a better professional look for the products.

Vehicle Graphics and Wraps

Peel-and-stick vinyls are extensively used as car decals and wraps for renovation, as well as for adding a protective barrier to the vehicles. Automotive enthusiasts prefer vinyl films over paint to revamp their vehicles and add a new pizzazz to them with partial wrap or full wraps.

Window Décor and Privacy Films

Clear vinyl films with frost detailings, i.e., frosted window film, are used to decorate windows in commercial and residential spaces. Because these are removable vinyl stickers, they allow you to update your indoor aesthetics whenever the season or your style changes.

Wall Murals and Floor Graphics

Adhesive-backed vinyls have also found their application in interior designing and renovation since these films can be customized in different prints, textures, and finishes. Instead of permanent paintwork, brands prefer wall vinyl wraps to display their branding.

Industrial Tags and Warning Labels

Self-adhesive vinyl sheets are also used to put labels and signs over equipment and machinery. They are used as warning labels to prevent hazards as well as instructional signage to provide clear operating guidelines.

Architectural Surface Refinishing

Specialized vinyls with wood grain and marble effect are employed in interiors to reface kitchen cabinets, doors, and other furniture pieces. Vinyl stickers serve as a superior option for renovation instead of repainting.

Key Advantages of Self-Adhesive Vinyl

Before choosing the adhesive-backed vinyls for your projects, you must know their advantages so that you can choose them confidently. In this section, we are highlighting the pronounced advantages of vinyl films that establish them as a premium option.

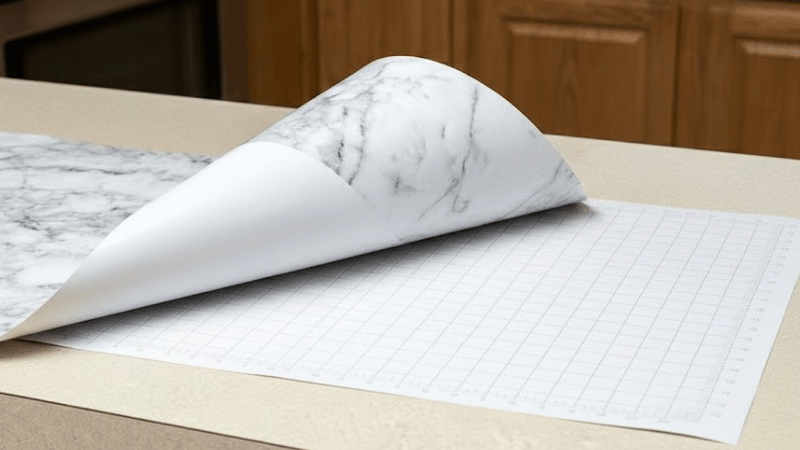

- Easy Application: These wraps can be easily installed over complex surfaces, from cars and furniture to floors and doors. Simply peel away the backing, position the film, apply pressure with a squeegee, and Voilà! Your surface is transformed without the mess of liquid glue.

- Wide Range of Finishes: Since the vinyl films are customizable, they come in a plethora of finishes that include gloss, metallic, matte, chrome, and many other premium finishes.

- Cost-Effective: Comparing the cost of vinyl with paintwork, the vinyl always stands out as a cost-effective option.

- Scalable: Vinyl films are suitable to be used as large billboards as well as for small signboards.

Helpful Tips for Using Self-Adhesive Vinyl

Surface Preparation

Before applying self-adhesive vinyl, it’s crucial to clean and degrease the surface to ensure strong adhesion. The surface must be smooth and dry to prevent any imperfections that could affect the vinyl’s bond.

Storage and Handling

Store vinyl rolls in a cool, dry place to maintain its quality and prevent adhesive failure. Handling the material with care and ensuring proper storage will help preserve its longevity and adhesive strength.

Application Environment

The ideal temperature for applying vinyl is between 60°F and 80°F (15°C to 27°C). This ensures the adhesive sticks properly. Avoid bubbles and lifting edges during application by using a squeegee to apply pressure evenly.

Conclusion

With their versatility and high performance, self-adhesive vinyl films have found their place in various industries. Whether you choose calendered, cast, or specialty vinyl, each of the vinyls has different properties and is suitable for different applications.

You can choose a type of vinyl depending on the nature of the application, as well as the lifespan expectation.

Multiply Your Sales with CarLike’s Self-Adhesive Vinyl Films

CarLike Film has been dealing in high-quality automotive film products since 2008 and has won the trust of businesses and industries from different niches. Start with just 10 rolls and enjoy custom OEM/ODM branding plus lightning-fast production and shipping.

Contact us today and request free samples of our high-quality self-adhesive vinyl sheets.

FAQs

Q1: Can I get samples before placing a bulk order?

Yes, Carlike offer samples so you can assess the quality and suitability of our vinyl products. Just contact us with your sample request.

Q2: Can self-adhesive vinyl be repositioned during installation?

Yes, a pressure-sensitive adhesive allows repositioning so that they can be lifted and adjusted to make sure they are applied correctly. Once the pressure is applied, it sets the bond of the adhesive to the surface.

Q3: Does self-adhesive vinyl damage paint upon removal?

No, if it is removed with the right removing tools, the vinyl does not damage the paint underneath.

Q4: Does self-adhesive vinyl provide any protective function?

Yes, self-adhesive vinyl is made to be UV-resistant so that it can protect the surface from UV damage and fading.